Note

Go to the end to download the full example code

Parametric study#

This example shows how you can use PyAdditive to perform a parametric study.

The intended audience is a user who desires to optimize additive machine parameters

to achieve a specific result. Here, the ParametricStudy class is used to

conduct a parametric study. While this is not required, the ParametricStudy

class provides data management and visualization features that ease the task.

Units are SI (m, kg, s, K) unless otherwise noted.

Perform required imports and create a study#

Perform the required import and create a ParametricStudy instance.

from ansys.additive.core import Additive, SimulationStatus, SimulationType

from ansys.additive.core.parametric_study import ColumnNames, ParametricStudy

import ansys.additive.core.parametric_study.display as display

study = ParametricStudy("demo-study")

Saving parametric study to /home/runner/work/pyadditive/pyadditive/examples/demo-study.ps

Get the study file name#

The current state of the parametric study is saved to a file upon each update. You can retrieve the name of the file as shown below. This file uses a binary format and is not human readable.

print(study.file_name)

/home/runner/work/pyadditive/pyadditive/examples/demo-study.ps

Select a material for the study#

Select a material to use in the study. The material name must be known by the Additive service. You can connect to the Additive service and print a list of available materials prior to selecting one.

additive = Additive()

print("Available material names: {}".format(additive.materials_list()))

material = "IN718"

user data path: /home/runner/.local/share/pyadditive

Available material names: ['316L', 'Ti64', '17-4PH', 'CoCr', 'IN718', 'IN625', 'AlSi10Mg', 'Al357']

Create a single bead evaluation#

Parametric studies often start with single bead simulations in order to

determine melt pool statistics. Here, the

generate_single_bead_permutations() method is used to

generate single bead simulation permutations. The parameters

for the generate_single_bead_permutations() method allow you to

specify a range of machine parameters and filter them by energy density. Not all

the parameters shown are required. Optional parameters that are not specified

use default values defined in the MachineConstants class.

import numpy as np

# Specify a range of laser powers. Valid values are 50 to 700 W.

initial_powers = np.linspace(50, 700, 7)

# Specify a range of laser scan speeds. Valid values are 0.35 to 2.5 m/s.

initial_scan_speeds = np.linspace(0.35, 2.5, 5)

# Specify powder layer thicknesses. Valid values are 10e-6 to 100e-6 m.

initial_layer_thicknesses = [40e-6, 50e-6]

# Specify laser beam diameters. Valid values are 20e-6 to 140e-6 m.

initial_beam_diameters = [80e-6]

# Specify heater temperatures. Valid values are 20 - 500 C.

initial_heater_temps = [80]

# Restrict the permutations within a range of energy densities

# For single bead, the energy density is laser power / (laser scan speed * layer thickness).

min_energy_density = 2e6

max_energy_density = 8e6

# Specify a bead length in meters.

bead_length = 0.001

study.generate_single_bead_permutations(

material_name=material,

bead_length=bead_length,

laser_powers=initial_powers,

scan_speeds=initial_scan_speeds,

layer_thicknesses=initial_layer_thicknesses,

beam_diameters=initial_beam_diameters,

heater_temperatures=initial_heater_temps,

min_area_energy_density=min_energy_density,

max_area_energy_density=max_energy_density,

)

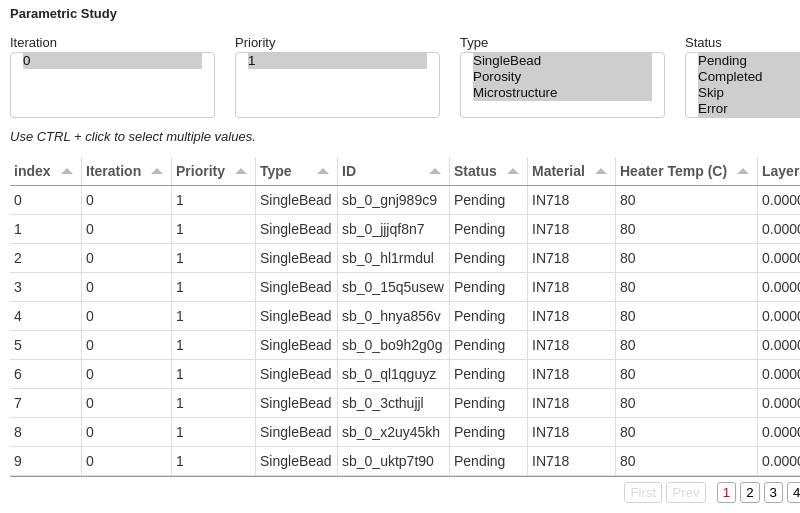

Show the simulations as a table#

You can use the display

package to list the simulations as a table.

display.show_table(study)

show_table

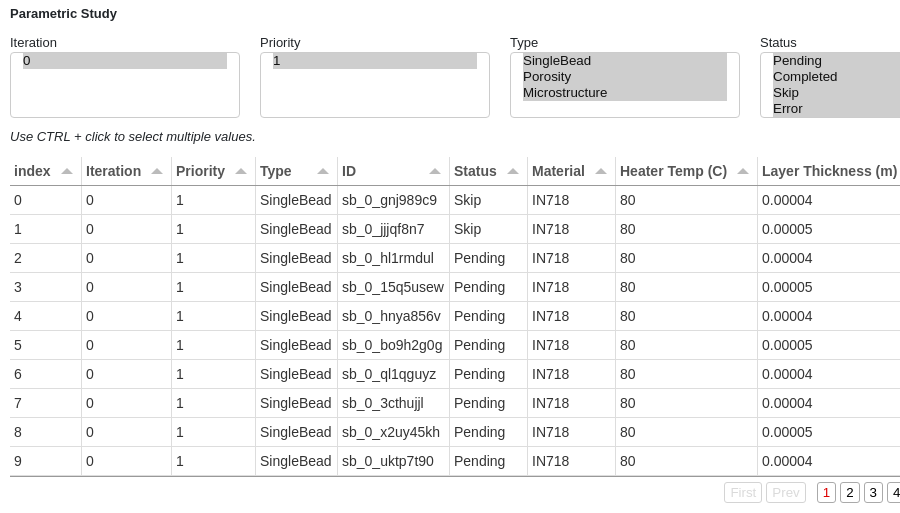

Skip some simulations#

If you are working with a large parametric study, you may want to skip some

simulations to reduce processing time. To do so, set the simulation status

to SimulationStatus.SKIP which is defined in the SimulationStatus

class. Here, a DataFrame object is obtained, a filter is

applied to get a list of simulation IDs, and then the status is updated on the

simulations with those IDs.

df = study.data_frame()

# Get IDs for single bead simulations with laser power below 75 W.

ids = df.loc[

(df[ColumnNames.LASER_POWER] < 75) & (df[ColumnNames.TYPE] == SimulationType.SINGLE_BEAD),

ColumnNames.ID,

].tolist()

study.set_status(ids, SimulationStatus.SKIP)

display.show_table(study)

show_table

Run single bead simulations#

Run the simulations using the run_simulations() method. All simulations

with a SimulationStatus.PENDING status are executed.

study.run_simulations(additive)

2024-02-21 03:22:39 Completed 0 of 31 simulations

2024-02-21 03:23:00 Completed 1 of 31 simulations

2024-02-21 03:23:14 Completed 2 of 31 simulations

2024-02-21 03:23:26 Completed 3 of 31 simulations

2024-02-21 03:23:38 Completed 4 of 31 simulations

2024-02-21 03:23:51 Completed 5 of 31 simulations

2024-02-21 03:24:04 Completed 6 of 31 simulations

2024-02-21 03:24:16 Completed 7 of 31 simulations

2024-02-21 03:24:28 Completed 8 of 31 simulations

2024-02-21 03:24:41 Completed 9 of 31 simulations

2024-02-21 03:24:53 Completed 10 of 31 simulations

2024-02-21 03:25:11 Completed 11 of 31 simulations

2024-02-21 03:25:22 Completed 12 of 31 simulations

2024-02-21 03:25:33 Completed 13 of 31 simulations

2024-02-21 03:25:47 Completed 14 of 31 simulations

2024-02-21 03:25:58 Completed 15 of 31 simulations

2024-02-21 03:26:10 Completed 16 of 31 simulations

2024-02-21 03:26:25 Completed 17 of 31 simulations

2024-02-21 03:26:37 Completed 18 of 31 simulations

2024-02-21 03:26:48 Completed 19 of 31 simulations

2024-02-21 03:27:01 Completed 20 of 31 simulations

2024-02-21 03:27:15 Completed 21 of 31 simulations

2024-02-21 03:27:30 Completed 22 of 31 simulations

2024-02-21 03:27:44 Completed 23 of 31 simulations

2024-02-21 03:28:05 Completed 24 of 31 simulations

2024-02-21 03:28:26 Completed 25 of 31 simulations

2024-02-21 03:28:39 Completed 26 of 31 simulations

2024-02-21 03:28:54 Completed 27 of 31 simulations

2024-02-21 03:29:08 Completed 28 of 31 simulations

2024-02-21 03:29:29 Completed 29 of 31 simulations

2024-02-21 03:29:45 Completed 30 of 31 simulations

2024-02-21 03:29:56 Completed 31 of 31 simulations

Save the study to a CSV file#

The parametric study is saved with each update in a binary format.

For other formats, use the to_* methods provided by the DataFrame class.

study.data_frame().to_csv("demo-study.csv")

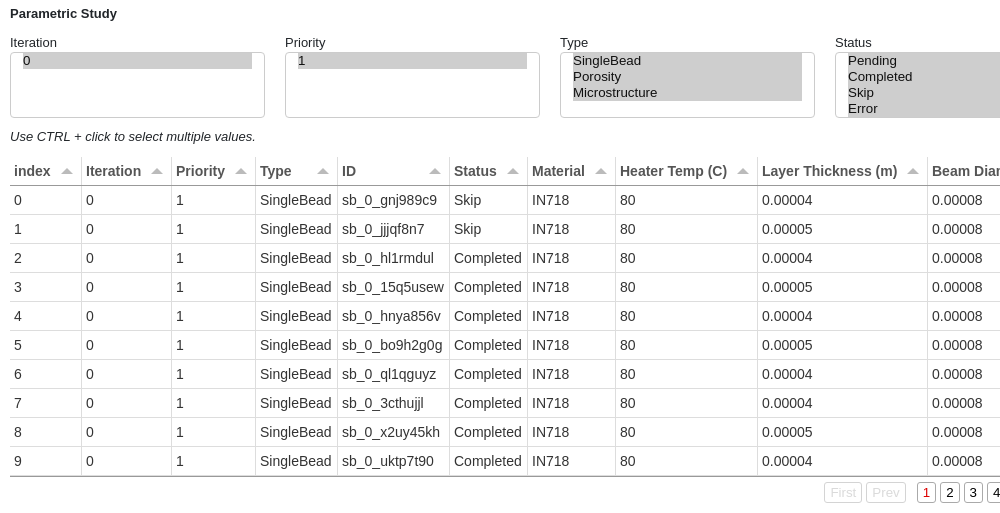

Load a previously saved study#

Load a previously saved study using the static

ParameticStudy.load() method.

study2 = ParametricStudy.load("demo-study.ps")

display.show_table(study2)

show_table

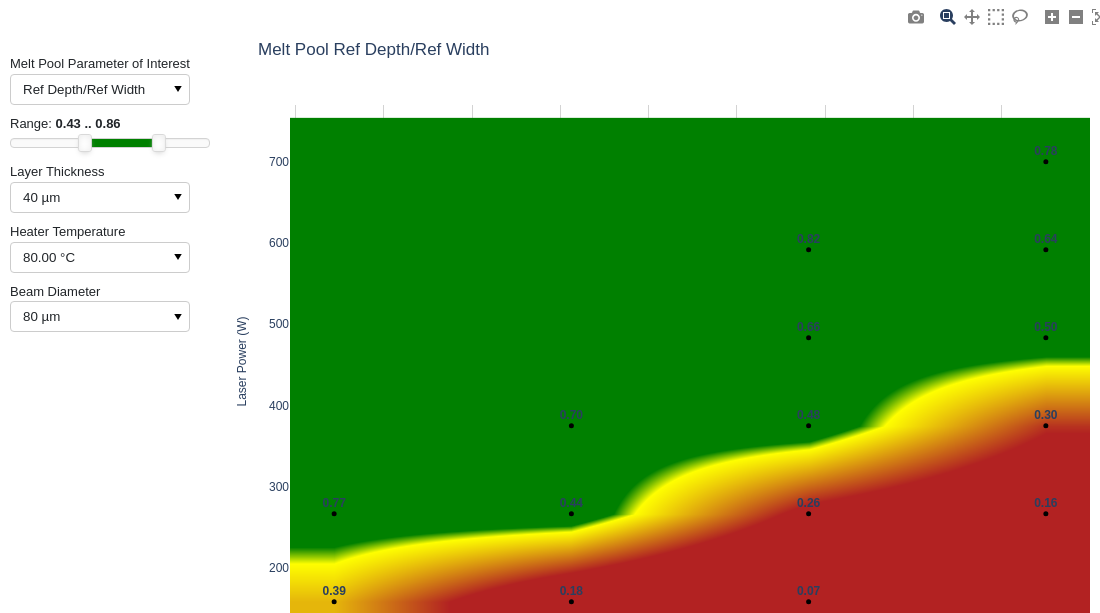

Plot single bead results#

Plot the single bead results using the

single_bead_eval_plot() method.

display.single_bead_eval_plot(study)

single_bead_eval_plot

Create a porosity evaluation#

You can use the insights gained from the single bead evaluation to

generate parameters for a porosity evaluation. Alternatively, you can

perform a porosity evaluation without a previous single bead evaluation.

Here, the laser power and scan speeds are determined by filtering the

single bead results where the ratio of the melt pool reference depth

to reference width is within a specified range. Additionally, the simulations

are restricted to a minimum build rate, which is calculated as

scan speed * layer thickness * hatch spacing. The

generate_porosity_permutations() method is used to add

porosity simulations to the study.

df = study.data_frame()

df = df[

(df[ColumnNames.MELT_POOL_REFERENCE_DEPTH_OVER_WIDTH] >= 0.3)

& (df[ColumnNames.MELT_POOL_REFERENCE_DEPTH_OVER_WIDTH] <= 0.65)

]

study.generate_porosity_permutations(

material_name=material,

laser_powers=df[ColumnNames.LASER_POWER].unique(),

scan_speeds=df[ColumnNames.SCAN_SPEED].unique(),

size_x=1e-3,

size_y=1e-3,

size_z=1e-3,

layer_thicknesses=[40e-6],

heater_temperatures=[80],

beam_diameters=[80e-6],

start_angles=[45],

rotation_angles=[67.5],

hatch_spacings=[100e-6],

min_build_rate=5e-9,

iteration=1,

)

Run porosity simulations#

Run the simulations using the run_simulations() method.

study.run_simulations(additive)

2024-02-21 03:30:00 Completed 0 of 15 simulations

2024-02-21 03:30:50 Completed 1 of 15 simulations

2024-02-21 03:31:27 Completed 2 of 15 simulations

2024-02-21 03:31:59 Completed 3 of 15 simulations

2024-02-21 03:32:53 Completed 4 of 15 simulations

2024-02-21 03:33:32 Completed 5 of 15 simulations

2024-02-21 03:34:05 Completed 6 of 15 simulations

2024-02-21 03:35:14 Completed 7 of 15 simulations

2024-02-21 03:35:57 Completed 8 of 15 simulations

2024-02-21 03:36:30 Completed 9 of 15 simulations

2024-02-21 03:38:29 Completed 10 of 15 simulations

2024-02-21 03:39:17 Completed 11 of 15 simulations

2024-02-21 03:39:52 Completed 12 of 15 simulations

2024-02-21 03:42:47 Completed 13 of 15 simulations

2024-02-21 03:43:59 Completed 14 of 15 simulations

2024-02-21 03:44:37 Completed 15 of 15 simulations

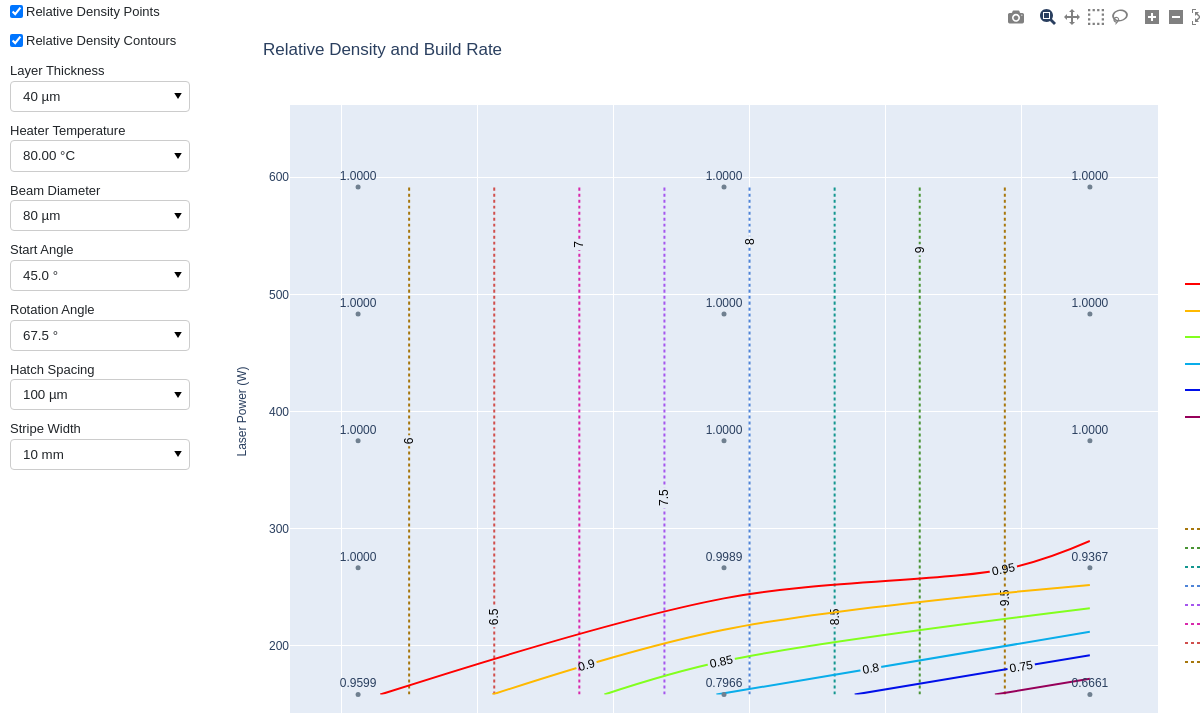

Plot porosity results#

Plot the porosity simulation results using the

porosity_contour_plot() method.

display.porosity_contour_plot(study)

porosity_contour_plot

Create a microstructure evaluation#

Here a set of microstructure simulations is generated using many of the same

parameters used for the porosity simulations. The parameters cooling_rate,

thermal_gradient, melt_pool_width, and melt_pool_depth are not

specified so they are calculated. The

generate_microstructure_permutations() method is used to add

microstructure simulations to the study.

df = study.data_frame()

df = df[(df[ColumnNames.TYPE] == SimulationType.POROSITY)]

study.generate_microstructure_permutations(

material_name=material,

laser_powers=df[ColumnNames.LASER_POWER].unique(),

scan_speeds=df[ColumnNames.SCAN_SPEED].unique(),

size_x=1e-3,

size_y=1e-3,

size_z=1.1e-3,

sensor_dimension=1e-4,

layer_thicknesses=df[ColumnNames.LAYER_THICKNESS].unique(),

heater_temperatures=df[ColumnNames.HEATER_TEMPERATURE].unique(),

beam_diameters=df[ColumnNames.BEAM_DIAMETER].unique(),

start_angles=df[ColumnNames.START_ANGLE].unique(),

rotation_angles=df[ColumnNames.ROTATION_ANGLE].unique(),

hatch_spacings=df[ColumnNames.HATCH_SPACING].unique(),

iteration=2,

)

Run microstructure simulations#

Run the simulations using the run_simulations() method.

study.run_simulations(additive)

2024-02-21 03:44:39 Completed 0 of 15 simulations

2024-02-21 03:46:52 Completed 1 of 15 simulations

2024-02-21 03:48:32 Completed 2 of 15 simulations

2024-02-21 03:49:56 Completed 3 of 15 simulations

2024-02-21 03:52:08 Completed 4 of 15 simulations

2024-02-21 03:53:50 Completed 5 of 15 simulations

2024-02-21 03:55:15 Completed 6 of 15 simulations

2024-02-21 03:57:32 Completed 7 of 15 simulations

2024-02-21 03:59:15 Completed 8 of 15 simulations

2024-02-21 04:00:40 Completed 9 of 15 simulations

2024-02-21 04:02:57 Completed 10 of 15 simulations

2024-02-21 04:04:44 Completed 11 of 15 simulations

2024-02-21 04:06:11 Completed 12 of 15 simulations

2024-02-21 04:08:32 Completed 13 of 15 simulations

2024-02-21 04:10:18 Completed 14 of 15 simulations

2024-02-21 04:11:49 Completed 15 of 15 simulations

Plot microstructure results#

Plot and compare the average grain sizes from the microstructure simulations

using the ave_grain_size_plot()

method.

display.ave_grain_size_plot(study)

ave_grain_size_plot

Total running time of the script: (49 minutes 40.241 seconds)